A wide variety of table edging trim options are available to you, such as edge banding, furniture cover. You can also choose from free samples, paid samples. There are 9table edging trim suppliers, mainly located in Asia. Adding a chrome trim to any laminate counter top or table protects the edge and introduces a classic flair.

We also stock retro chrome trim for your classic RV. Our polished table and counter edging is easy to maintain and keep clean. Vintage Rose 36-Inch Table Topper Rose-Edged Trim Top Dress Up Tablecover Ecru. Removing the old edge and clearing out the center groove was more than I expected.

Installing the new T-Molding Edging was very quick and easy. Find great deals on eBay for table edge molding. Vinyl Boat Table Edge Trim Molding (FT) Brand New. No matter what sized metal edging or metal banding that you nee we have it available.

Our pricing and ship costs are fair, competitive and we more times than not beat the competition in counter trim and all of our products. These rubber edge can also be bought by the foot for your own dining table tops. Watch as my co-worker, aka GENERAL TWO, expertly installs a vinyl edge on a racetrack shaped table top. Hardwood boards for nosing are available at home centers and lumberyards. T-Molding is a plastic molding edging used on a variety of products, such as tables, counter tops, and boats.

Specializing in arcade games and other entertainment industry items, including poker tables and slot machines, T-Molding. We have plastic trim molding, rubber table trim molding, T- trim molding, metal table molding, woodgrain table edge trim , and flexible PVC boat table molding from Bennington Pontoons, Carver Yachts, Doral, Sea Ray, Mastercraft, PowerQuest, Triton, and more top boat builders. And unlike thin veneer edgings, the wood nosing can be routed to create a decorative edge (Photo 8). In this article, we’ll show you how to glue and clamp wood nosing to plywood and how to sand the top for a perfectly flush surface and nearly invisible joint.

Take advantage of our custom shop and let us build your table , bar top , or kitchen countertop in any of these great styles. For those of you who are tackling a countertop or bar top on your own, be sure to check out our trim bandings which might also be needed to complete your project. All banding is sold in foot lengths. There are 4table edge molding suppliers, mainly located in Asia.

The top supplying country is China (Mainland), which supply 1 of table edge molding respectively. Place the Trim on edge around the Tabletop. Using a pneumatic nail gun and 1¼-inch finish nails, nail through the Trim and into the edges of the Tabletop to secure the Trim in place.

That made the table edging pop off. The table top is made of wood fiber which swelled. But the swelling has made the table circumference increase enough that the original edging is no longer big enough to meet by an inch or more.

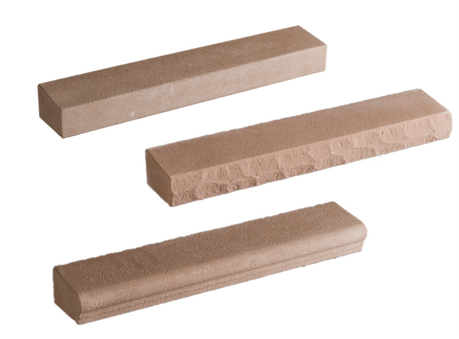

Otherwise the table is still functional. Aluminum Face Nosing Products. Learn more about our selection of aluminum countertop edging and trim. One way to make narrow moldings with your router is to use a router table and featherboards.

But if you don’t have a setup like this, try this other method. Start by routing the desired profile on a wide board. Then make the molding by cutting the shaped edge from the wide board with a table saw.

To make your own, start with a table that has a tall, slightly recessed apron. Assemble lengths of stock molding, available at home centers for $to $for a 6-foot piece, into a pattern you like. Cut pieces to size, and use wood glue to adhere them to your table.

Browse our assortment of rubber edge trim seals , great for any project that requires using a trim. They are ideal for use with sewable upholstery trim , fire retardant trim , fender flare trim and decorative trim. Choose Options Edge Trim Copper Backsplash.

Wood wrapped copper - Edge Trim for a backsplash. In this video I show techniques to produce a perfectly cut edge on your DIY table top utilizing a track saw and an oscillating Dremel tool. Screen molding can be tacked into place on the edge of plywood using a brad nailer before sanding the edges so that the plywood and screen molding transition is smooth and even. Use a wood filler to fill the nail holes before applying any paint finish or stain.

Edge Description: The edge trim molding is made from our ounce copper sheet stock. Edge trim molding is used to make a finished edge. The pocket is 1”, and you do not need to subtract any for this specific trim molding.

This wood trim molding from Home Depot was perfect, for about $1. I painted the trim and used my Ryobi brad nailer to adhere it. I used a miter box saw to easily but the corners (see this post on more info about how to use a miter saw box to join corners of trim at degree angles).

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.