Solid granite surface plate and angle plates are used for precision layout, inspection and tooling setup. STANDRIDGE is known for high accuracy calibration service and repair on all granite surface plates and granite inspection accessories. On-Site Service for granite surface plate is offered on a daily basis in our Southern California area. Accredited Calibration is available.

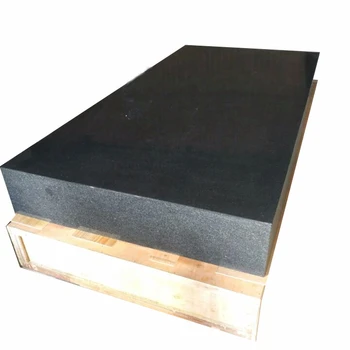

Our high-quality black granite surface plates provide the strongest, most durable and stable surfaces available. The Repeat-O-Meter is the instrument that is used to check the repeatability, or small wear spots that occur from normal everyday use. Tru-Stone granite surface plates and granite inspection plates meet or exceed all of the requirements set forth in this specification.

At present, there is no defining specification for granite angle plates , parallels, or master squares. Aging through hundreds of millions years, the granite can still retain even character, stable, high strength and hardness, and can keep high precision at heave duty. Surface Plate Accessories. STANDRIDGE granite surface plates provide an accurate reference plane for work inspection and for work layout. Their high degree of flatness, overall quality and workmanship also make them ideal bases for mounting sophisticated mechanical, electronic and optical gauging systems.

High hardness granite inspection surface plate is in black color with bright, homogeneous structure, good stability, high hardness, anti-rust and chemical-resistance. Cored Bench Plates come in and models and can be used as fixture bases or small surface plates. Your granite surface plate ( granite block, granite table) is the foundation of all accurate measurements, Optimal Calibration has the ability to achieve extremely tight tolerances to ensure that your are getting the most precise measurements possible.

Before use, be sure the granite surface plate is always used on the support system furnished with the plate. Find great deals on eBay for granite surface plate and granite surface plate x 24. GRANITE INSPECTION SURFACE PLATE X X 4. A surface plate is a soli flat plate used as the main horizontal reference plane for precision inspection , marking out layout, and tooling setup. The intervals between each surface plate calibration depends on the condition of the environment where the surface plate is located. Precision Granite , Accurate, Excellent Value.

Nagar, Bengaluru, Karnataka. For many shops, inspection rooms and laboratories, precision granite surface plates are relied on as the basis for accurate measurement. Because every linear measurement depends on an accurate reference surface from which final dimensions are taken, surface plates provide the best reference plane. Our 48x60xinch high-quality black precision granite surface plates are MADE IN THE USA and provide the strongest, most durable and stable surfaces available. You may choose a workshop grade plate or a high precision one.

Granite is a material of choice for plates with smooth, non-abrasive surfaces. This tool room grade B Granite Plate has a bilateral accuracy of plus or minus. SURFACE PLATES The majority of our surface plates are produced with charcoal black granite. Upon request, we can also manufacture black diabase, pink or gray plates as well. Plates are produced to meet or exceed federal specification GGG-P-463c.

Final inspection of our surface plates is done with an autocollimator or electronic levels and. The surface plate is used as a reference plane for precision inspection , layout and tooling setup around the world. The new shop will have a climate controlled inspection room with a 96x72xgranite inspection table.

These precision granite surface plates are precision lapped to high standards of flatness to achieve accuracy and are used as bases for mounting sophisticated mechanical, electronic and optical gauging systems. The granite table will have a welded I-Beam stand. Many laboratories and shops rely specifically on granite surface plates for precise measurement and inspection. Ltd belong to MORN GROUP LIMITE located in the high-tech development zone in Jinan city, north of China. Our company is the professional manufacturer and exporter of mechanical granite plate , granite inspection table, granite precision stage, granite base, granite ruler and other relevant granite parts.

First of all, rigorous quality control inspection is carried out at all stages. Used on the shop floor or in your quality room, this table is available with a full complement of inspection tooling. Starrett Granite Inspection Table. Made of high quality Jinan Black Granite.

High precision and high stability. No rust and anticorrosion. Granite plates have good temperature stability, are resistant to corrosion, are nonmagnetic and distortion free and make an excellent surface for accurate marking out. After the long-term natural aging, the granite inspection plate is uniform in structure, and has low coefficient of linear expansion.

The internal stress has completely disappeare which means no deformation will be found. Therefore, our product offers high precision. My inspection equipment is probably most lacking in the category of a quality surface plate. I have two, technically, but I only use one for machining.

A certificate of accuracy, traceable to the National Institute of Standards and Technology, is furnished with all surface plates. Charcoal Black granite is standard except for plates larger than 48” x 72” which are Sierra Grey.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.