An epoxy resin table is durable and long-lasting, making it a fun and popular choice for homes projects and restaurants. The notable feature of epoxy resin tables is the ability to seal objects and memorabilia within the epoxy resin , enabling you to create a unique table that showcases your interests and hobbies. Next I figured out how much epoxy resin I needed for my epoxy resin table DIY pour. Epoxy Resin Wood Table Top - Duration:. One part hardener one part resin.

If you check on countertop epoxy website you will find a chart to help you with square footage coverage. I used gallon and quarts of the epoxy resin coating. Step One: Prepare your tabletop. This concern can be eliminated if you cover the glitter with epoxy resin , or better yet mix it into the epoxy to give your table or bar top the ultimate sparkle. If you are going to glitter your counters or table , you have two options.

Find and save ideas about Resin table on Pinterest. In this case, I’m concerned that the bottom surface of the table will expand in width as it absorbs humidity, but the top surface won’t because it it sealed with epoxy. This will cause the top to cup upwards and crack the epoxy.

I poured the resin having levelled my table top using a spirit level, and used a heat gun to dissipate the bubbles that formed. In about hours the whole thing was safe to touch and had completely cured inside hrs. Mine was a 1:ratio of epoxy resin to hardener and I added a metallic blue pigment to the mix. Once your resin is mixe slowly begin to pour it into your table top. Alcohol ink is an inexpensive liquid pigment that is popular amongst choices for epoxy resin dye.

That is due to its opacity, while still retaining the ability to be transparent when placed in front of light. Many creators use this as the pigment of choice when creating table top masterpieces, and for good reason. It is very important to properly clean the tabletop before coating it with epoxy resin for finish because the resin will make dirt stick to the table.

Sometimes, it so happens that there are dry stains on the table top. Our table top epoxy is easy to use and DIY you can do it yourself. Mix it pour it and use it in your table hours.

We have been selling our table top epoxy for over years to comercial contractors, restaurants, chains, bar owners and homeowners. Footer Get fresh Etsy trends and unique gift ideas delivered right to your inbox. Use a sander to smooth and level the top of your future table top. While things are still dusty, use a wire brush to scrape away some of the bark.

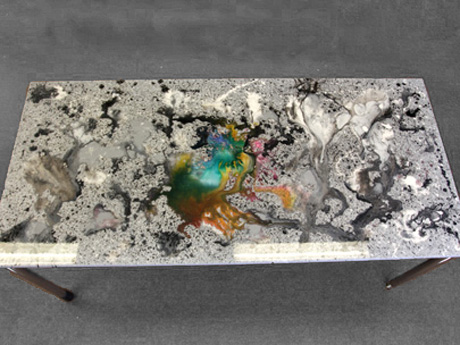

Next, use a vacuum to suck up any dust that has gotten trapped in the nooks of your piece. Here is the mixing process I used: 12oz. Table top epoxy pigments in resin and molds are easy to figure out so you can do almost anything with them. Being able to re-create the natural beauty of an Agate or Geode, or even a river table or a lava flow table in epoxy are super cool ways to get creative and express yourself with a really fun new way of coating.

UV resistant countertop or bar top epoxy. Ideas for Resin Table Tops Resin table tops are usually covered by an epoxy polymer that has been poured onto the table top and sets hard to form a finished surface. They provide firm, durable and lasting table or bar top surfaces. Whether you want to perfect your bar or counter top , or simply using it to create a table , there are tons of creative projects you can do. Using epoxy resin can truly make your work stand out.

DIY projects are always fun to plan and develop over time. If you want the appearance of coats of varnish with just one pour, look no further than our Table Top Epoxy. This 1:epoxy system provides you with a protective glass-like finish on any surface. Next, I put a generous coat of Johnson Paste Wax on the bottom, sides, and top of box where the particle board was exposed. If you really want a thin table top , a carbon fiber backer would be the thinnest, followed probably by steel, and then plywood (which would be lighter but thicker than the steel).

TL;DR, there are much cheaper and more effective ways to create a clear or semi clear table top compared to pure resin. Alumilite Amazing Clear Cast is a high gloss, durable, diverse and easy to use epoxy resin perfect for bar tops, table tops, display tops, or craft projects that require a protective coating. Part A is the resin and part B is the hardner.

A crystal clear glass like finish. Cut a piece that’s small enough to allow a layer of epoxy over the top. Then adhere it by pressing it into a bed of epoxy. UV Stable Crystal Clear Table Top System is a high performance two component Clear epoxy system designed for Table Tops, Bars, Wood finishes, See-Through Encapsulations, Artwork, and other applications requiring a clear, strong, plastic coating specifically designed to resist Yellowing caused by the sun and other Ultra Violet.

DIY resin river table liquid clear epoxy casting resin table top glue is a high performance double component Clear epoxy system designed for wood table tops, firniture, woodworking, artwork. Each kit contains a bottle of resin and a bottle of hardener. The lower part of a table - top in the place where will pour out epoxy resin has to be from polyethylene or an adhesive tape.

If to use plastic or wood in order that epoxy resin did not pour out after it stiffens plastic or a tree it will be impossible to disconnect from a table - top. You can use bar top epoxy resin coating for wood from leading brands like Marine Supplies to create a unique and creative DIY live edge table. These are high-performance 2-part epoxy systems specially designed for wooden table tops and bars, art work, wood finishes and other applications that require a clear and strong coating.

A custom coffee table is a great way to make a unique statement.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.